Machining for industries in need of critical parts for their machines and operations is not something L&H takes lightly. We are committed to consistently providing precision manufacturing for customers around the world in mining, oil and gas, power generation and the railroad industries. It’s important that our customers can count on us to provide the best products in the industry; that’s why our expert tradesmen are skilled to work on some of the most advanced machining technology in the world.

Investing in new technologies to continually advance quality and efficiency has lead L&H to where we are today; a global leader in manufacturing parts for some of the largest machines in the world including NASA’s crawler transporter. With the purchase of a new 5-axis machining center, L&H will again bring new technology to their precision manufacturing operations.

Drilling, tapping, milling and more

L&H’s new state of the art double column machining center will hold more than 94,000 lbs of table load with a spindle operating at 4,000 rpm’s and 11 x 10 feet of travel on the x and y axis. The 5-axis machining center’s column construction ensures greater rigidity and closer tolerances; bringing another level of capacity to L&H’s manufacturing capabilities.

Preparing for the arrival of the new machine

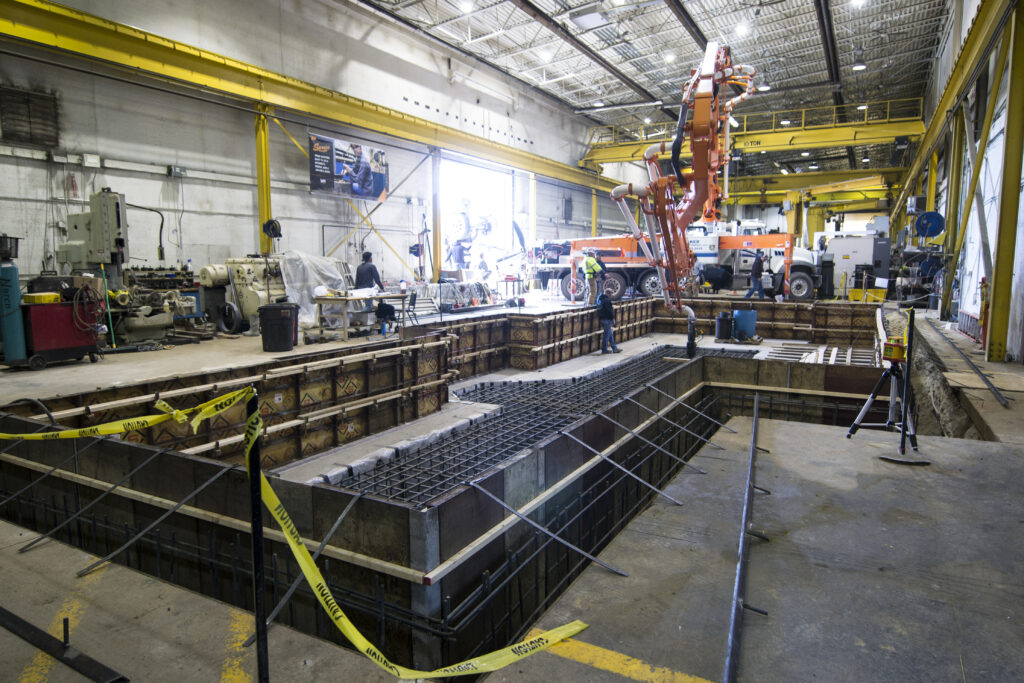

The new machine will be installed and operational in June, but in the meantime L&H is busy preparing for its arrival. Digging a thirteen foot pit topped with a 7 seven foot concrete pad, the machine will require extensive support. A geotechnical engineer helped design a structure plan to ensure a solid foundation.

Laying a foundation for the new machine

L&H ordered the machine in October of 2015, and the machine is expected to arrive and be running in June. Mike Doherty, Senior Engineer, commented,

“L&H has come together on this project to keep things running smoothly; the machine, mechanic and weld shops as well as oilfield, purchasing, engineering and management have all worked together.”