drills

Drill Down

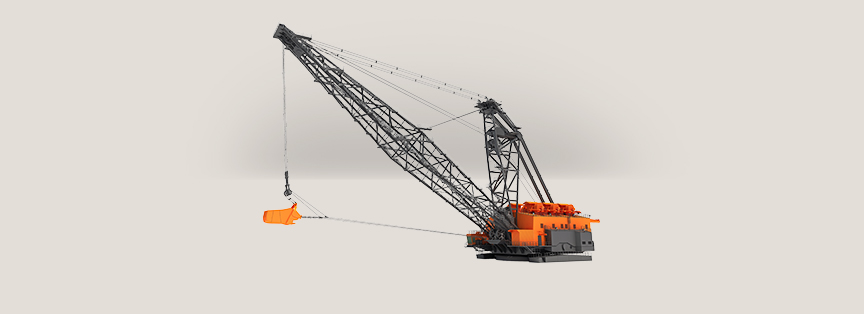

When a mining drill breaks down, production comes to a standstill. Our teams of specialists are ready to keep your operations on track with design, engineering, manufacturing, monitoring, and field services. We improve blasthole drills in mines around the world with the insights our field experts gain by working every day on equipment in the most demanding environments in the industry.

Improving Operations

If you can’t drill, you can’t blast. The experts at L&H Industrial will have you back to drilling and filling blastholes fast and operating more smoothly and with less downtime than ever before. We transform complete blasthole drill systems, including new undercarriage technology, downhole components, masts, and other components that improve operating efficiency and equipment life. We back up that work with 24/7 precision field and maintenance services.

Rebuilding Better

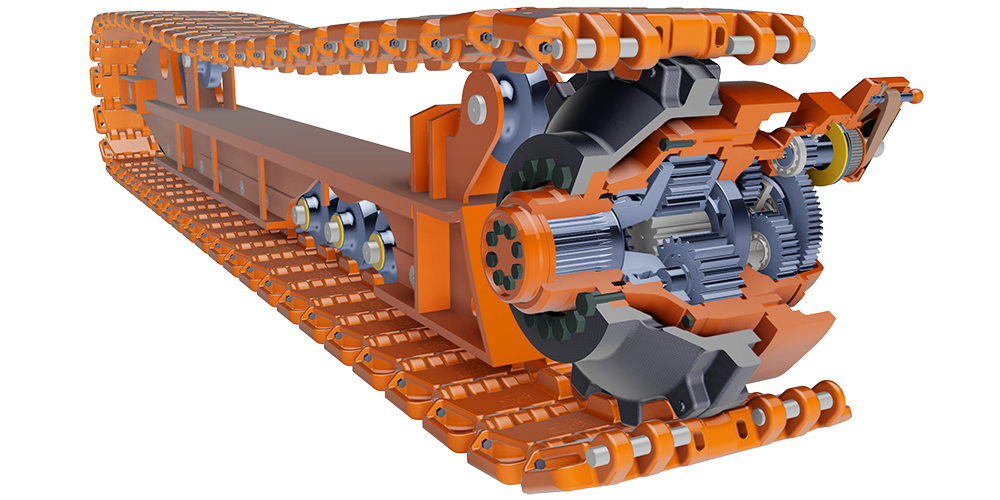

We radically improve blasthole drills and other heavy mining machinery with stronger materials and designs that offer longer component life, including our unique trackpad design, that delivers better machine maneuverability. With complete solutions for all parts of mining drills, we rebuild, repair, and replace everything from the undercarriage assemblies and trackpads to the cylinders, drill masts, and rotary gearboxes. When you partner with L&H, you’ll be back in business with a better machine than the one you started with.

L&H Innovations

We pair our superior design, engineering, manufacturing, and monitoring capabilities with a nimble and practical partnership approach. Our industry-leading solutions transform the operating efficiencies for blasthole drilling in mining operations around the world.

Direct REplacements

Count on our 60 years of industry experience and expertise to maximize on-site mining drill repair jobs, from trackpads, cylinders, and pins, to masts, gearboxes, drill steels, and sideframes. L&H replacement components minimize downtime and help you meet your production goals.

Custom Solutions

No job is too complex for our expert design, engineering, and manufacturing teams. We’ll handle whatever you need—from major outages and complete upgrades to critical component overhauls and custom blasthole drilling solutions.

Simply

unmatched

Components

100% of L&H premium components meet, or more often exceed, OEM performance, quality, and safety standards.

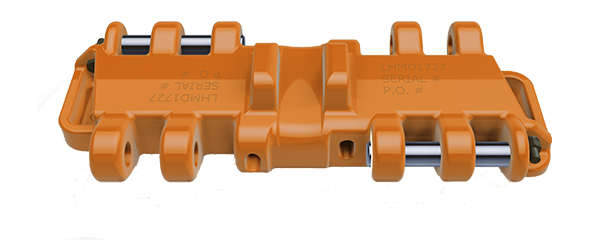

Crawler Shoes

Premium design and manufacturing improved component geometry to offer reduced wear rate and pitch for longer life and better performance.

ready for increased productivity?

Components & Assemblies We Enhance

Mainframe

· Leveling jacks

· Catwalks

Mast

· Mast/tower structures

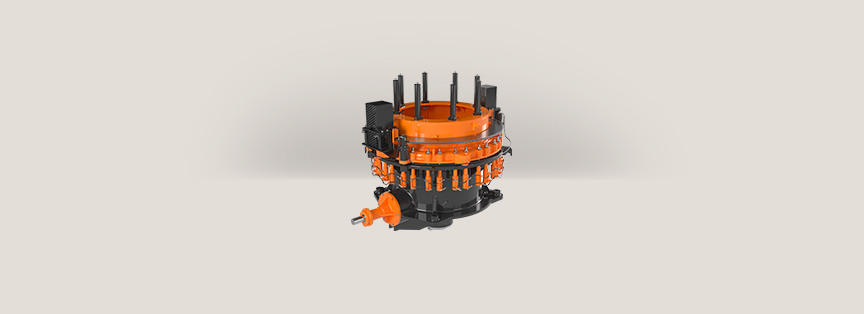

· Rotary head gearboxes

· Pull down guide frames

· Break out wrenches

· Carousel assemblies

· Shock subs

Propel Assembly

· Trackpads

· Propel transmissions

· Drive tumblers

· Shoes + pins

· Trackpads + chains

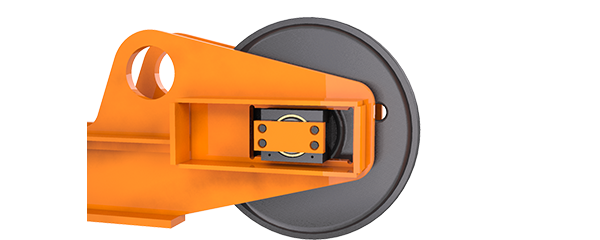

· Take-up idlers

· Lower rollers

· Upper rollers

· Side frames

· Axles

Hydraulic

· Cylinders

· Pump drives

· Controls

Down hole

· Drill steels

· Consumables

· Saver subs

Brands We Make Even Better

Field Services We Offer

· Complete audits and inspections

· Rush breakdown repairs

· Failure analysis & troubleshooting

· Full machine audits & inspections

· Equipment relocations

· Machine upgrades

Technical Data Sheets

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.