processing

equipment

Crushing Benchmarks

We know the key to crushing your business goals is efficient and dependable processing equipment. L&H offers complete solutions that optimize your quarry operation. With 60 years of experience working shoulder-to-shoulder with our industry partners, our expert teams repair, rebuild, and customize machines, components, and assemblies to transform any make and model of equipment used for crushing, grinding, conveying, screening, washing, and classifying with full lifecycle partnership.

Improving Operations

Why keep losing time making the same repairs on your cone crusher, jaw crusher, or mobile crushing plant, when L&H can completely transform your stationary processing equipment or mobile crusher, screens, or classifier? With a focus on unrivaled design and premium materials, our enhancements reduce downtime, improve safety, increase production, and lower your cost of ownership. Our engineering and technical field support teams understand your operation and equipment, so we don’t just fix machines, we make them perform better to meet your production goals in your unique environment.

Rebuilding Better

The L&H design, engineering, manufacturing, and field service experts leverage 60 years of globally respected experience to transform mobile and fixed processing plant equipment. With our OPS IQ monitoring and controls program, you can track machine health and performance to reduce downtime and make data-driven decisions. Our enhancements will have you back up and running with equipment working more efficiently and safely so you can focus on what’s most important—crushing, screening, and loading out product with improved throughput.

L&H Innovations

We combine our superior design, engineering, manufacturing, and field service capabilities with a flexible, practical partnership approach. Our industry-leading innovations include a cone crusher tramp release with a remote digital power unit that improves safety and reduces maintenance and downtime, transforming legacy mineral processing equipment into smart machines in quarries around the world.

Direct REplacements

For 60 years we’ve gained expert experience that we bring to quarries of every size, from the most straightforward and to the most complex operations. Our replacements for crushing, and screening are unmatched. Our repairs and maintenance provide you the service you come to expect. Our high-quality replacement parts are manufactured with premium alloys to maximize safety and minimize downtime so you can focus on hitting your throughput targets.

Custom Solutions

You don’t need to wait for your OEM to design a better machine. L&H routinely designs, engineers, and manufactures custom machines, components, and assemblies in-house with full lifecycle support from our team of experts. We’re one of only two companies in North America with a Höfler Rapid 6000 6-meter gear grinder, producing AGMA 12 quality or better gears, pinions, and pinion shafts.

Simply

unmatched

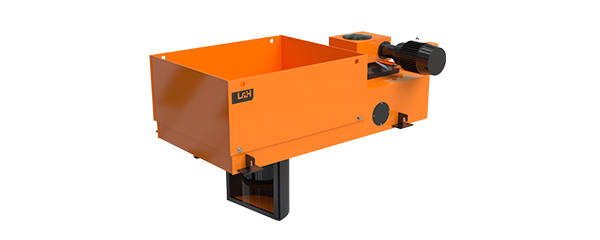

Apron Feeder Shaft Assembly

Eliminates ring feeder on sprocket housings and the need to remove motors and bearings if plates get damaged, while protecting against timing misalignments.

Gearing

In-house AGMA 12 finish and up to 6M diameter gears provide lead, profile, spacing, and bending resistance with less pitting, quieter, cooler operation, and longer gear life.

Transmission Rebuilds

For most makes, models, and sizes from seals and bearings to full gear trains with vibration analysis, thermography, and precise reporting to deliver the right results for vertical and horizontal transmissions

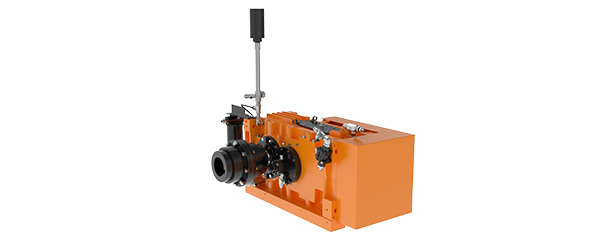

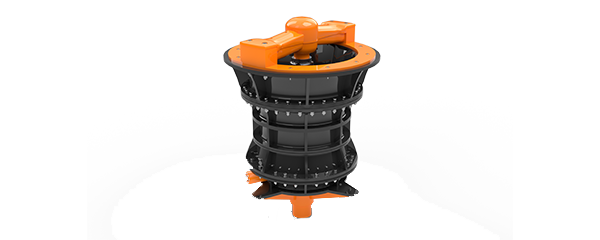

Digital power unit

Compact design and minimal footprint offer seamless installation and bowl removal, reducing downtime and maximizing efficiency with safer remote monitoring and controls.

Tramp release system

Using monitoring and controls and our digital power unit, the system auto-adjusts the bowl to safely remove un-crushables from the system, reducing manual adjustment downtime.

Components

100% of L&H premium components meet, or more often exceed, OEM performance, quality, and safety standards.

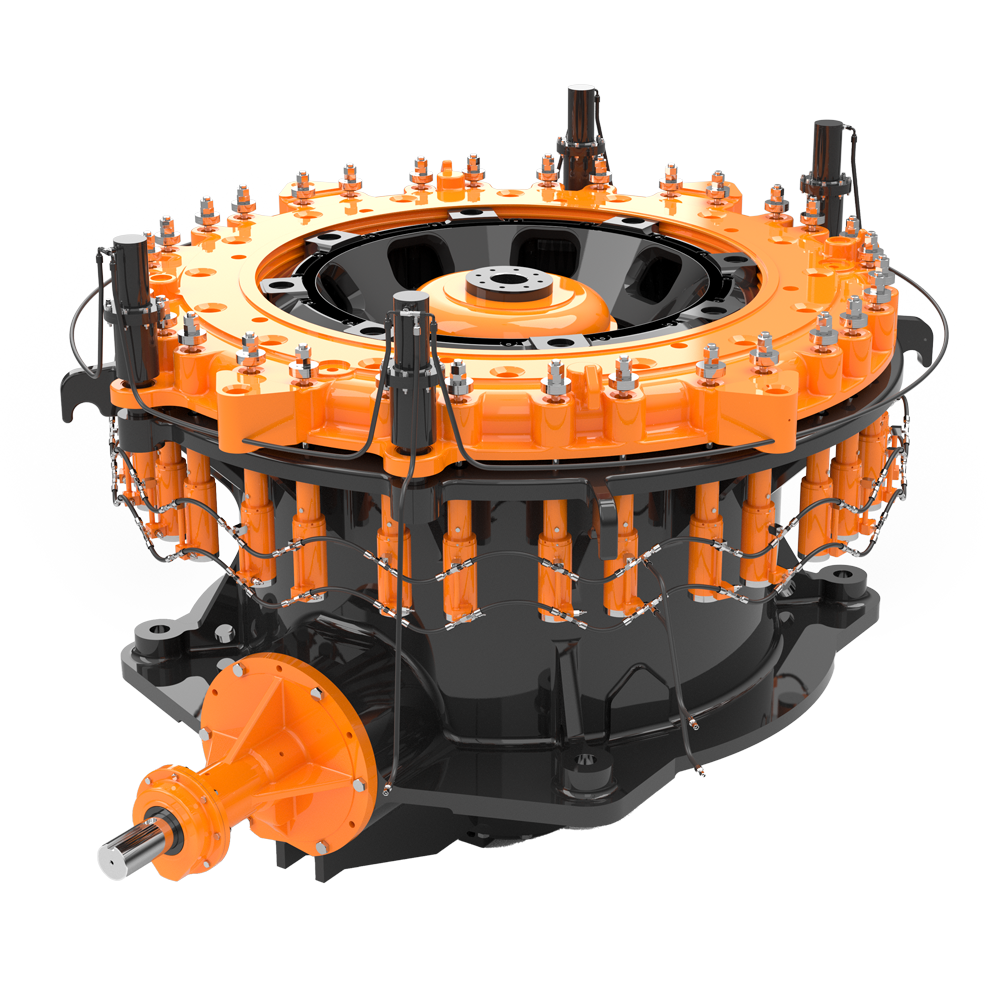

Crusher Rebuilds

200% output increase with on-site large gyratory crusher repair, in-house component repair, lubrication and hydraulic controls, and new components for legacy crushers.

Ready for increased productivity?

Equipment, Components & Assemblies We Enhance

Crushers

· Cone crushers

· Gyratory crushers

· Roll crushers

· Jaw crushers

· Hammer mills

· Vertical shaft impactors

· Shaft rotary shear shredder

Crusher Components & assemblies

· Main shaft

· Eccentric

· Countershaft

· Mainframe

· Bowl

· Adjustment ring

Power & Hydraulic Cone Crusher Offerings

· Tramp release system for Symons®

· Super duty lock posts for Symons

· Super duty ram cylinders for Symons

· Hydraulic clamping and adjustment conversion

· Kits for Symons

· Rotating feed distributors

· Lube systems

· Cooling systems

· HPU’s (Hydraulic Power Units)

CONCENTRATION & DEWATERING EQUIPMENT

· Thickeners

· Agitators

· Aerators

· Clarifiers

Feed & Support equipment

· Apron feeders

· Screens

· Conveyors

· Stackers

· Hydraulic hammers

· Head/tail pulley

· Sprockets

· Bearings

· Tripper car bogie wheel assemblies

· Wheels

Brands We Make Even Better

Field Services We Offer

· New installation or repair

· Inspections and maintenance

· Teardowns and relocations

· Failure analysis and troubleshooting

· Planned upgrades

· Machine customizations

· Equipment-specific training

Brochures

Case Studies

Proven Solutions From Our Trusted Partners

We are proud to build partner relationships that expand our value through distributing quality solutions from trusted brands in operations across heavy industry. These partners share our commitment to the highest quality and safety standards, responsive service, and constant drive for innovation.

Have A Big

Challenge?

We’re ready for anything.

No problem is too big or too small. Our expert engineers, manufacturers, and field service technicians love a good challenge and routinely solve complex issues for operations globally.